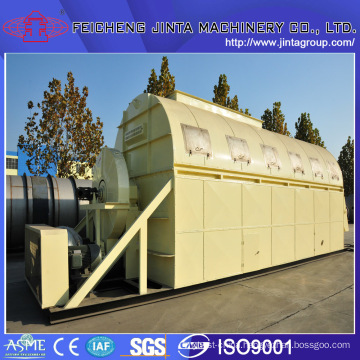

Ddgs Series Tube Bundle Dryer

Ddgs Series Tube Bundle Dryer

| Payment Type: | L/C, T/T, Western Union |

|---|

| Place of Origin: | Shandong, China |

|---|

Product Description

Structure: Rotary Type Drier Operation Pressure: Atmospheric Dryer Appearance of Dried Sample: Pastes Movement Way: Combined Type of Atomization: Pressure Atomization Packing:Nonwoven Cloth or Nude Packing: Standard: ISO9001: Asme, SGS, Iaf, GB Liquid Flow Rote: as Per Design: Production Capacity: 200set/Month Specification: CE, SGS, ASME, IAF Operational Method: Continuous Drying Medium: Superheated Steam Heating Mode: Convective Type of Flow: Contra-Flow Sprayer: Pressure-Type Trademark: Jinta or OEM: Origin:Shandong China Trademark: JINTA Origin: Shandong, China The Spiral Plate Heat Exchanger

1. Company Information

FEICHENG JINTA MACHINERY Co., Ltd. Is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China. We can design and manufacture mechanical equipments for clients all over the world.

2. Product Description:

DGS Series Tube Bundle Dryer is a kind of drying equipment adopting thermal conduction and heat radiation to conduct the heat, the material inlet, returning and outlet of which can be accomplished continuously.

3. Application:

It can be widely applied in the drying of material with high moisture in chemical industry, light industry and pharmacy, which can adjust the drying time according to material features and moisture requirements, with the features of high automation, clean environment and steady operation.

4. Production Capability

10. Our company was established in the 1950s, designed and manufactured the first stainless steel Distillation Column in China.

2). Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGS section) in a month.

3). Among 16 production workshops, 3 workshops are for mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshops are for assembling & welding.

5. Package & Transport

Our company can package the products according to export standard and use container with reinforcement measures.

6. After-sales Service

Our company can provide a sophisticated product after-sale service and can ensure the implementation, maintenance and commission of projects.

If you have any questions, pls feel free to contact us

Name: Jessie Hao

Phone: 86 13705382911

Tel: 86-538-3393566

Fax: 86-538-3399066

Contact us if you need more details on Spiral Heat Exchanger. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Heat Exchanger、Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Company Information

FEICHENG JINTA MACHINERY Co., Ltd. Is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China. We can design and manufacture mechanical equipments for clients all over the world.

2. Product Description:

DGS Series Tube Bundle Dryer is a kind of drying equipment adopting thermal conduction and heat radiation to conduct the heat, the material inlet, returning and outlet of which can be accomplished continuously.

3. Application:

It can be widely applied in the drying of material with high moisture in chemical industry, light industry and pharmacy, which can adjust the drying time according to material features and moisture requirements, with the features of high automation, clean environment and steady operation.

4. Production Capability

10. Our company was established in the 1950s, designed and manufactured the first stainless steel Distillation Column in China.

2). Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGS section) in a month.

3). Among 16 production workshops, 3 workshops are for mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshops are for assembling & welding.

5. Package & Transport

Our company can package the products according to export standard and use container with reinforcement measures.

6. After-sales Service

Our company can provide a sophisticated product after-sale service and can ensure the implementation, maintenance and commission of projects.

If you have any questions, pls feel free to contact us

Name: Jessie Hao

Phone: 86 13705382911

Tel: 86-538-3393566

Fax: 86-538-3399066

| Model No. | HE Area (m2) | Main Drive Power (KW) | Design Pressure (MPa) | Steam Moisture Ratio (kg/kg) | Overall dimension |

| L*W*H (mm) | |||||

| DGS--80 | 80 | 7.5 | 0.7 | 1.4~1.5 | 7200×1600×2000 |

| DGS--100 | 100 | 7.5 | 0.7 | 1.4~1.5 | 7400×1800×2200 |

| DGS--150 | 150 | 11 | 0.7 | 1.4~1.5 | 7600×2000×2300 |

| DGS--210 | 210 | 11 | 0.7 | 1.4~1.5 | 7800×2100×2550 |

| DGS--250 | 250 | 15 | 0.7 | 1.4~1.5 | 7800×2400×2600 |

| DGS--300 | 300 | 18.5 | 0.7 | 1.4~1.5 | 8200×2500×2600 |

| DGS--350 | 350 | 22 | 0.7 | 1.4~1.5 | 8500×2600×3100 |

| DGS--400 | 400 | 30 | 0.7 | 1.4~1.5 | 8500×2800×3320 |

| DGS--500 | 500 | 37 | 0.7 | 1.4~1.5 | 9500×2800×3320 |

| DGS--600 | 600 | 55 | 0.7 | 1.4~1.5 | 10000×3000×3550 |

| DGS--800 | 800 | 75 | 0.7 | 1.4~1.5 | 10700×3200×3900 |

| DGS--1000 | 1000 | 90 | 0.7 | 1.4~1.5 | 11000×3600×4100 |

| DGS--1200 | 1200 | 110 | 0.7 | 1.4~1.5 | 11500×3800×4400 |

| DGS--1500 | 1500 | 160 | 0.7 | 1.4~1.5 | 13000×4000×4600 |

Product Categories : Spiral Heat Exchanger

Premium Related Products

Other Products

Hot Products

Alcohol/ Ethanol Distillation Column Tower Plant Nt Making Machinery Dehydration ColumnStainless Steel Columns Petrochemical IndustryAsme Standard Pressure Tank CondenserCarbon Steel Air Cooled Condenser (V100)Distillation Machinery Column Tower Dehydration Column for Sale Made in ChinaAlcohol Distillation Equipment China ManufactureHigh Effect Roller Dryer for DdgsSpiral Plate Heat Exchanger (Non-Detachable)Evaporator for Alcohol/Ethanol Equipment Line China ManufacturerSA516gr 70 Carbon Steel Chemical Reactor R016VAC Stripper Tower C102bStainless Steel Reactor with Half PipeTpsa Vessel Air SeperatorDual Media Pressure Filter Pressure Vessel Carbon SteelCarbon Steel Reactor with Agitator SystemPressure Vessel Flare Stacks F001