Plate Type Heat Exchanger

Plate Type Heat Exchanger

| Payment Type: | L/C, T/T, Western Union |

|---|

| Place of Origin: | Shandong, China |

|---|

Product Description

Application: Heater, Cooler, Vaporizer, Condenser, Heater Style: Plate Type, Plate Plates Material: Stainless, Ti Heat-Exchange Plate: SUS304, SUS316L, Smo254, Titanium, Nickel, Hastel Clamping Bolt: Galvanized Carbon Steel, Stainless Steel Guide Bar: Galvanized Carbon Steel, Stainless Steel Type: Stainless Steel Heating Equipment Structure Material: Metal Material Mixing Heat Exchanger Type: Jetheat Exchanger Trademark: Jinta or as Per Requirement Origin: Shandong, China Principle: Mixing Heat Exchanger Frame: Material:Carbon Steel Size and Material: Can Be Worked as Per Client Requirement Gasket Seal: NBR, H-NBR, EPDM, Food Pad, Fluorine Rubber, Silic Interface: Rubber, Carbon Steel, Stainless Steel Ceramic Heating Equipment Type: Ceramic Electric Heater Recuperative Heat Exchanger Type: Double Tube Sheet Heat Exchanger Heat Transfer Surface: Plate Heat Exchanger Core: Core Evaporative Heat Exchanger Specification: CE, ISO9001, GB, ASME, SGS HEAT EXCHANGER OF ALL KINDS PROFESSIONAL MANUFATURER

Advantage of plate heat exchanger

1. Small volume, Low investment, operation and maintenance costs.

2. Highly efficient heat transfer- Heat transfer coefficient is 3000~6000W/M2. ° C, Which is high average 3~5times.

3. More effectively cooling and heating

4, Easy to fit, add or change plate.

5. Convenient disassembly, cleaning, maintenance and repair

6. Environmental protection

Company feature

1. Focus on heat exchanger

2. Pay attention to client's require

3. Reply massage at the first time

4. Delivery in time

Working principle

Heat exchanger type: Gasket Plate heat exchanger

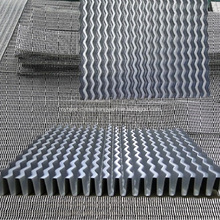

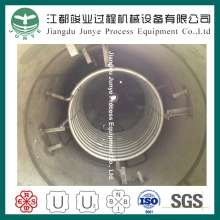

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of the two fluids between which heat transfer will take place. The plate pack is assembled between a fix frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket which seals the inter plate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of the fluids, pressure drop and temperature program. The plate corrugations promote fluid turbulence and support the plates against differential pressure. The frame plate and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar, both of which are fixed to a support column. Connections are located in the frame plate or, if either or both fluids make more than a single pass within the unit, in the frame and pressure plates.

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Application

Food industry: Milk pasteurization Milk and beverage pasteurization, Wine tempering, Bottled water treatment, CIP (Cleaning-in-Place) heating, Reverse osmosis water.

Marine application: Central cooling of the main or auxiliary engines or turbines, Lubrication oil cooling, Re-cooling of circulated water for cooling cylinders, pistons, injection nozzles, Cooling of oil, compressor oil and other lubricants, Preheating of lubrication oil and heavy fuel oil, Preheating of seawater for fresh water production, Heat recovery, Heat exchange to air-condition the passengers' cabins and freight spaces

Others: Turbine oil cooler, Chemical industry, district heating, district cooling, swimming pool heating, solar heating, textile printing & dyeing industry, pharmacy, food, chemical, paper making, steel and electromechanical and so on

Warranty

We promise 10 year guarantee, all reasonable relevant cost will be undertaken by us in the first year if our heat exchanger fail to work due to quality problem,

More information, please feel free to contact us.

Name: Jessie Hao

Phone: 86 13705382911

Tel: 86-538-3393566

Fax: 86-538-3399066 Contact us if you need more details on Plate Heart Exchanger. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Heat Exchanger、Heater. If these products fail to match your need, please contact us and we would like to provide relevant information.

Advantage of plate heat exchanger

1. Small volume, Low investment, operation and maintenance costs.

2. Highly efficient heat transfer- Heat transfer coefficient is 3000~6000W/M2. ° C, Which is high average 3~5times.

3. More effectively cooling and heating

4, Easy to fit, add or change plate.

5. Convenient disassembly, cleaning, maintenance and repair

6. Environmental protection

Company feature

1. Focus on heat exchanger

2. Pay attention to client's require

3. Reply massage at the first time

4. Delivery in time

Working principle

Heat exchanger type: Gasket Plate heat exchanger

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of the two fluids between which heat transfer will take place. The plate pack is assembled between a fix frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket which seals the inter plate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of the fluids, pressure drop and temperature program. The plate corrugations promote fluid turbulence and support the plates against differential pressure. The frame plate and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar, both of which are fixed to a support column. Connections are located in the frame plate or, if either or both fluids make more than a single pass within the unit, in the frame and pressure plates.

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Application

Food industry: Milk pasteurization Milk and beverage pasteurization, Wine tempering, Bottled water treatment, CIP (Cleaning-in-Place) heating, Reverse osmosis water.

Marine application: Central cooling of the main or auxiliary engines or turbines, Lubrication oil cooling, Re-cooling of circulated water for cooling cylinders, pistons, injection nozzles, Cooling of oil, compressor oil and other lubricants, Preheating of lubrication oil and heavy fuel oil, Preheating of seawater for fresh water production, Heat recovery, Heat exchange to air-condition the passengers' cabins and freight spaces

Others: Turbine oil cooler, Chemical industry, district heating, district cooling, swimming pool heating, solar heating, textile printing & dyeing industry, pharmacy, food, chemical, paper making, steel and electromechanical and so on

Warranty

We promise 10 year guarantee, all reasonable relevant cost will be undertaken by us in the first year if our heat exchanger fail to work due to quality problem,

More information, please feel free to contact us.

Name: Jessie Hao

Phone: 86 13705382911

Tel: 86-538-3393566

Fax: 86-538-3399066 Contact us if you need more details on Plate Heart Exchanger. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Heat Exchanger、Heater. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Heat Exchanger > Other Heat Exchanger

Premium Related Products

Other Products

Hot Products

Alcohol/ Ethanol Distillation Column Tower Plant Nt Making Machinery Dehydration ColumnStainless Steel Columns Petrochemical IndustryAsme Standard Pressure Tank CondenserCarbon Steel Air Cooled Condenser (V100)Distillation Machinery Column Tower Dehydration Column for Sale Made in ChinaAlcohol Distillation Equipment China ManufactureHigh Effect Roller Dryer for DdgsSpiral Plate Heat Exchanger (Non-Detachable)Evaporator for Alcohol/Ethanol Equipment Line China ManufacturerSA516gr 70 Carbon Steel Chemical Reactor R016VAC Stripper Tower C102bStainless Steel Reactor with Half PipeTpsa Vessel Air SeperatorDual Media Pressure Filter Pressure Vessel Carbon SteelCarbon Steel Reactor with Agitator SystemPressure Vessel Flare Stacks F001